Materials #

When you’re in school, you have relatively limited resources. Here are a few families of materials and fabrication methods that you may be able to use.

- cardboard and foamcore + X-Acto knife and hot glue

- 3D-printed PLA or TPU, possibly with heat-set inserts

- laser-cut acrylic, plywood, MDF or chipboard

- construction lumber + miter saw, band saw, and table saw

- 80/20 structural aluminum framing + miter saw and drill press

- sheet metal + tin snips, jump shear, and box brake

- Aluminum or steel + lathe and mill

Once you get to industry, you have more choices– LOTS MORE.

Aluminum #

There are at least 530 different aluminum alloys. For only $150, you can buy the ANSI H35.1 standard and read all 12 pages (includes appendix).

Alternatively, here are a few guidelines that will help you get your bearings. (That’s almost a pun, but bearings are made of 440C steel, not aluminum.)

| Alloy | Composition | Most common example |

|---|---|---|

| 1xxx | pure (>99%) aluminum | 1100 |

| 2xxx | alloyed with copper | 2024 |

| 3xxx | alloyed with manganese | 3003 |

| 4xxx | alloyed with silicon | ??? |

| 5xxx | alloyed with magnesium | 5052 |

| 6xxx | alloyed with Mg2Si | 6061 |

| 7xxx | alloyed with zinc | 7075 |

-

1100: easy to form, cheap

-

3003: easy to form, cheap, but a little stronger

-

5052: strong, great corrosion resistance, not heat-treatable

-

6061: strong, good corrosion resistance, heat-treatable, machines well

-

2024: very strong, still formable

-

7075: even stronger, less formable, better corrosion resistance

-

7075-T6: the most bad-ass aluminum

Reminder about fatigue: aluminum fatigues; steel doesn’t.

Steel #

Steel = iron + carbon (0.04% - 1.5%)

You can read about different steel alloys in the SAE A29 standard, only $56 for 17 pages (almost 4x cheaper than the H35.1 aluminum standard!).

Generally, the last two digits of the alloy designation are the carbon concentration by mass in hundredths of a percent.

| Alloy | Composition | Example |

|---|---|---|

| 1xxx | plain carbon steels | 1010, 1018 |

| 2xxx | nickel | |

| 3xxx | nickel-chromium | |

| 4xxx | molybdenum | 4130 (gears), 4140 (stiffer, harder) |

| 5xxx | chromium | 5160 |

| 6xxx | chromium-vanadium | |

| 7xxx | tungsten | |

| 8xxx | nickel-chromium-molybdenum | |

| 9xxx | silicon-manganese |

Tool steel #

| Designator | Description |

|---|---|

| A2 | Air hardening |

| M2 | Machine tool cutters |

| O1 | Oil hardening |

| S2 | Shock resistant |

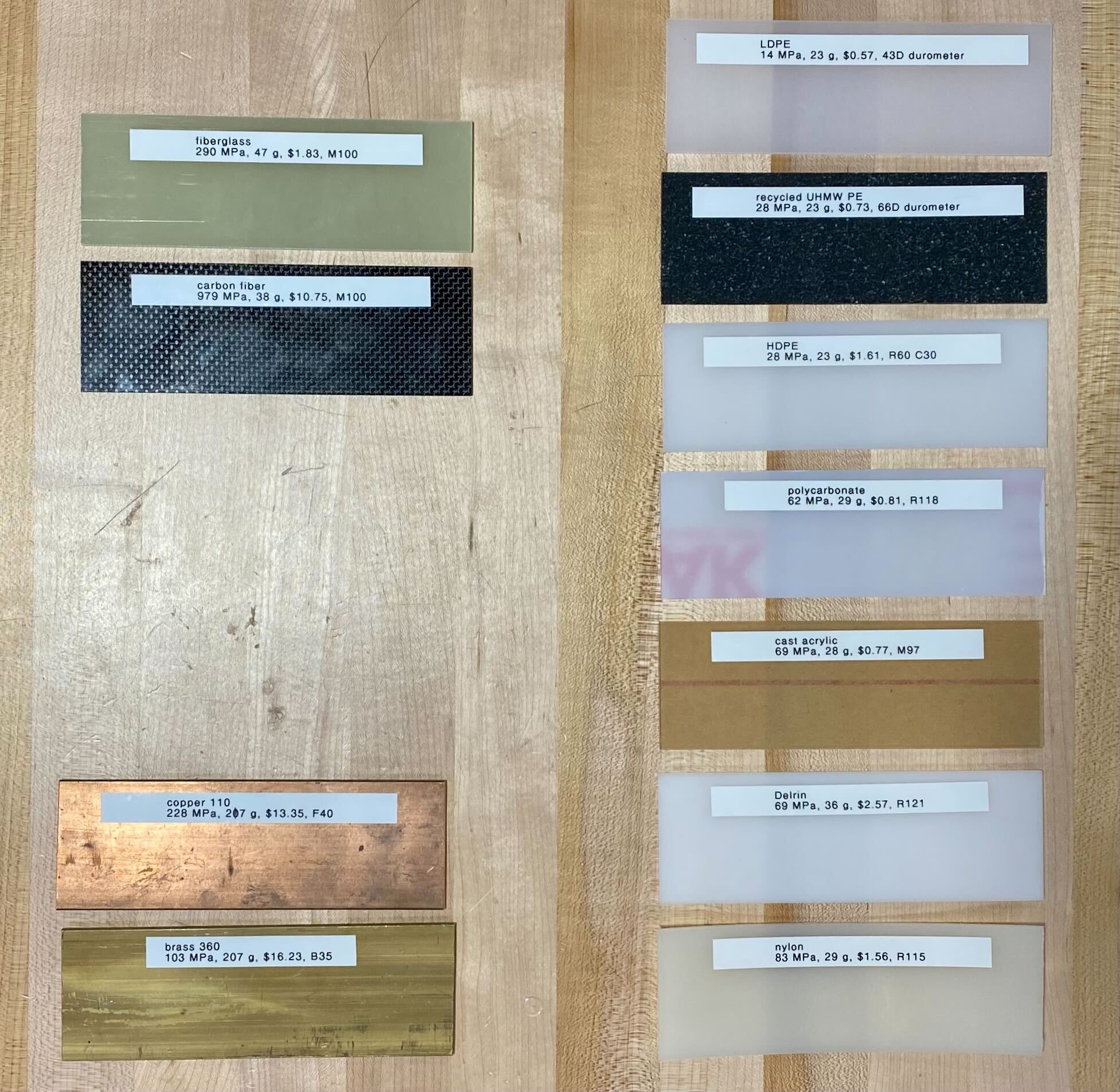

Materials gallery #

Here’s what these materials look like.

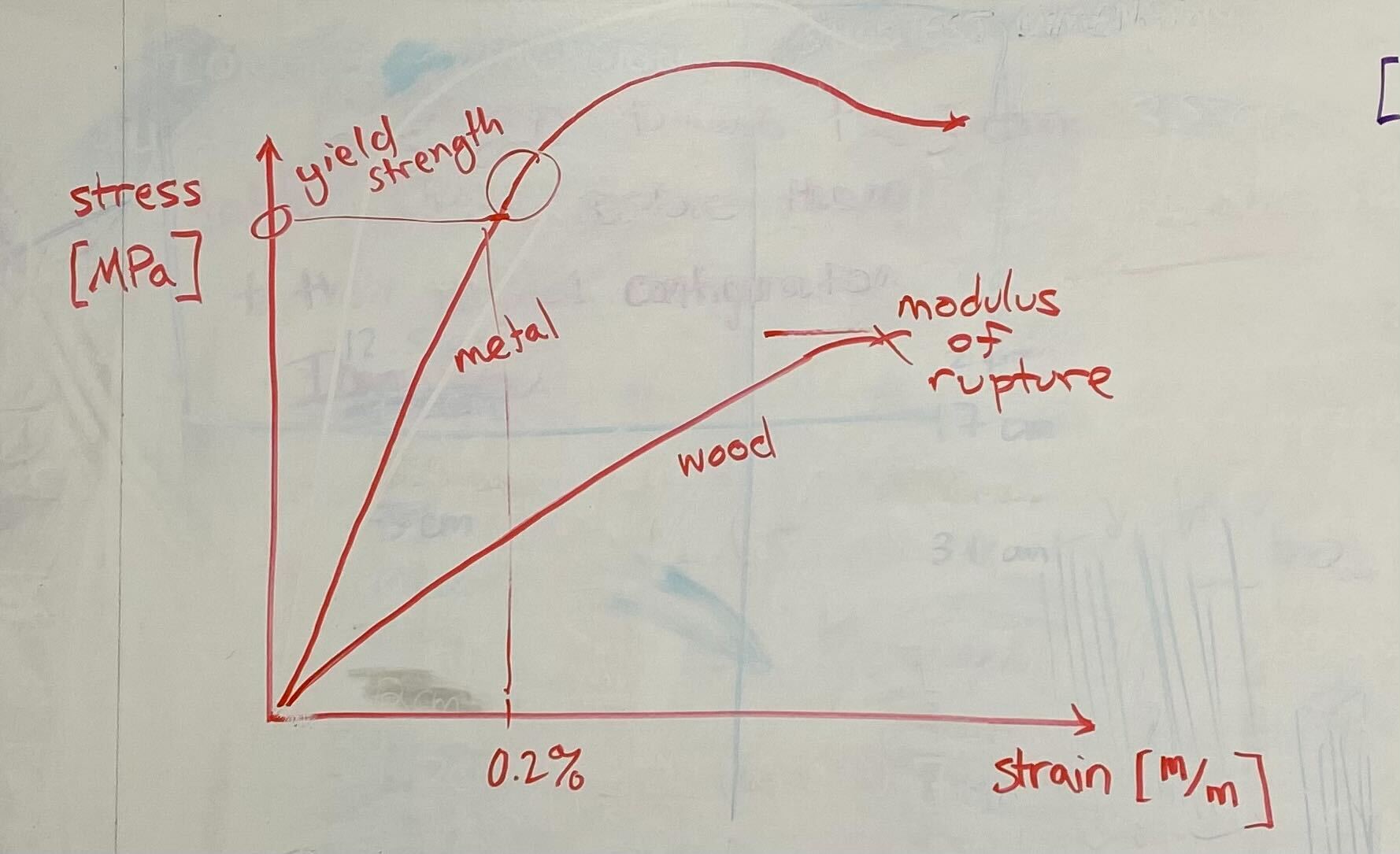

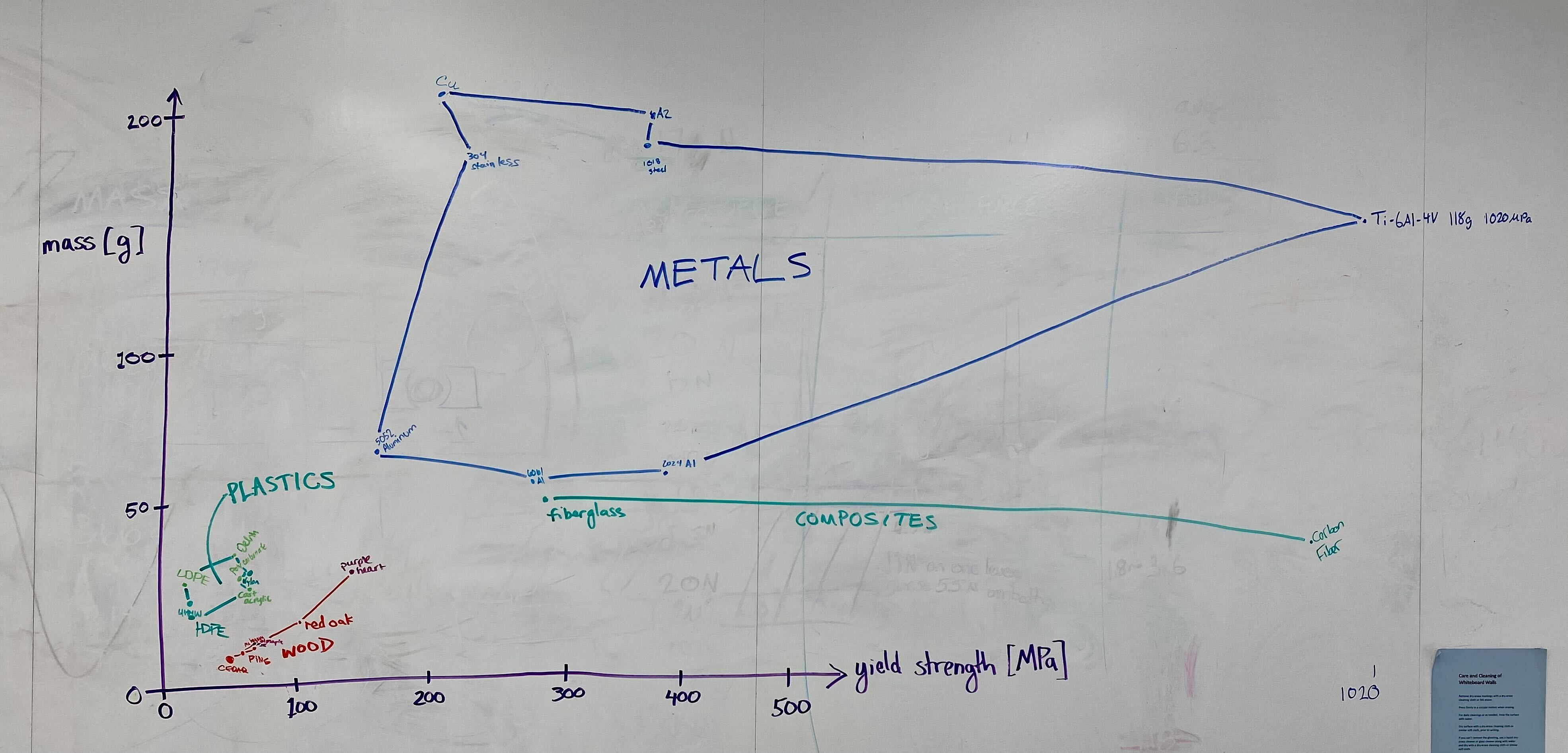

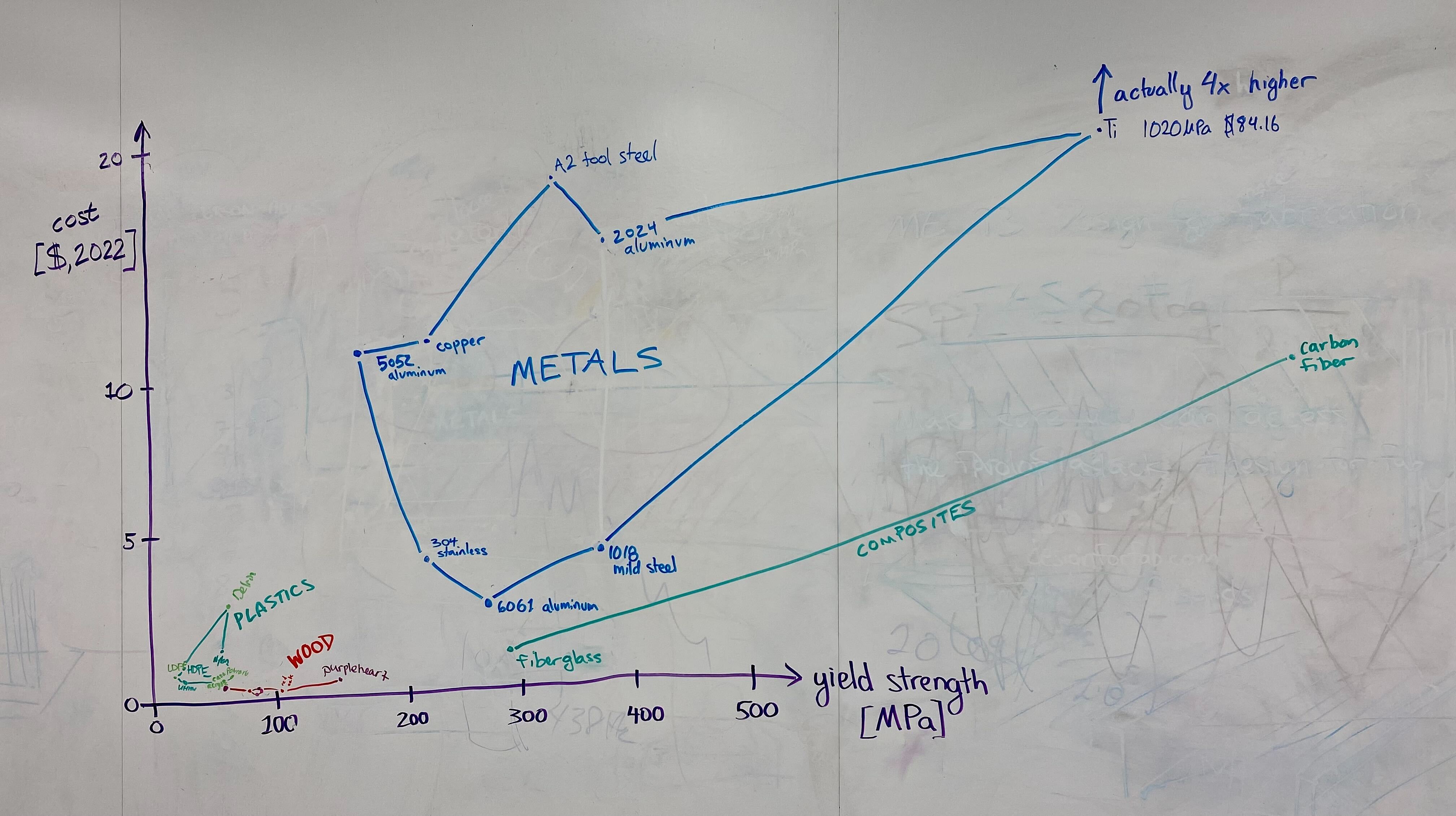

Yield strength tradeoffs #

Notes on material usage, based on notes taken by Ananya Ram (thanks!) #

Plastics: #

- LDPE → milk jug material, cheap

- HDPE → stronger, terrible for the environment, can’t really be machined

- MDPE → recycled material, still terrible for the environment

- Polycarb sheet → like acrylic, but can absorb a lot of energy (high energy toughness)

- Acrylic → can’t machine because it shatters~~

- Delrin → optimized for machining

- Nylon → super strong plastic, some are stronger than steel

Composites #

- Fiberglass → boats, super stiff

- Carbon fiber → also super strong, $$,

Woods: good for lightweight structures #

- Pine → cheapest, lightest, crappiest material

- Cedar → even lighter than pine, eh about everything else. Smells good briefly…

- Fir → Pine 2.0, stiff, tables and long-term stuff

- Mahogany → looks nice, fancy furniture

- Maple → hard, for cutting board

- Red Oak → heavier means stronger, and it’s very strong, good for floors

- Baltic Birch Plywood → plywood = alternating grain

- Purple Heart → one of the densest woods that you can just buy

Metals, usually alloys: #

- Copper → thermally conductive, expensive, not an alloy

- 1018 Steel → crappy steel, still expensive (nice but heavy)

- Stainless Steel 304 → same as mild steel, non-magnetic, doesn’t rust (nice but heavy)

- A2 Tool Steel → air-hardened steel, very uniform, used for knives (nice but heavy)

- 6061 Aluminum → cheapest aluminum engineers use

- 5052 Aluminum → easily formed or welded

- 2024 Aluminum → used for airplanes etc. extra stiff allow

- Brass → copper + zinc(?); mostly used for aesthetic

- Titanium → $84, stiffest material